- (989) 317-8033

- 801 Industrial Dr, Mt Pleasant, MI 48858

- Mon - Fri: 8:00 AM - 5:00 PM

Deep Draw Presses

Drawing brass or copper cups to finished or near net shape.

Cupping Press

Presses for forming cup from strip or wire.

Bullet Assembly Press

Assembling lead cores and copper jackets.

OTM-5000 – Neck & Taper

The OTM-5000 is a neck and taper press for finishing rifle cartridges. This machine comes standard with OTM upgraded hardened feed system, carbide quick change tooling, and state of the art PLC controls.

Run Rates In Parts Per Minute

- 223/5.56 – 60-70 PPM

- 7.62×39 – 60-70 PPM

- 7.62×51 – 55-60 PPM

- 338 Lapua – 45-50 PPM

Press Details

- Tonnage: 45 Ton

- Electrical: 220/480V

- Stroke: 5″

- Coolant Capable: Yes

- Max Caliber Size: 338 Lapua

- Drive Type: Servo With Controllable Motion Paths

Previous

Next

OTM-5100 – Deep Draw Pistol

The OTM-5100 is a servo draw press with a slower part per minute high accuracy output. The servo capability has features such as tool temperature adjustment, multi program memory, and a adjustable head. This machine comes standard with OTM upgraded hardened feed system, carbide quick change tooling, and state of the art PLC controls.

Run Rates In Parts Per Minute

- 380 ACP – 60-70 PPM

- 9MM – 60-70 PPM

- 40 S&W – 55-60 PPM

- 45 ACP – 45-50 PPM

Press Details

- Tonnage: 45 Ton

- Electrical: 220/480V

- Stroke: 4″

- Coolant Capable: Yes

- Max Caliber Size: 500 S&W

- Drive Type: Servo With Controllable Motion Paths

Previous

Next

OTM-5150 Deep Draw Rifle

The OTM-5150 is a servo draw press with a slower part per minute high accuracy output. The servo capability has features such as tool temperature adjustment, multi program memory, and a adjustable head. This machine comes standard with OTM upgraded hardened feed system, carbide quick change tooling, and state of the art PLC controls.

Run Rates In Parts Per Minute

- 223/5.56 – 50-60 PPM

- 7.62×39 – 50-60 PPM

- 7.62×51 – 45-55 PPM

- 338 Lapua – 40-45 PPM

Press Details

- Tonnage: 80 Ton

- Electrical: 220/480V

- Stroke: 6″

- Coolant Capable: Yes

- Max Caliber Size: 338 Lapua

- Drive Type: Servo With Controllable Motion Paths

Previous

Next

OTM-5250 – Cupping Press

The OTM-5250 is a wire form cupping press for rifle and pistol cartridges, servo driven features such as tool temperature adjustment, multi program memory, and an adjustable head set us apart from the competition. Cupping from wire allows you to have virtually no scrap and less processing cost. This machine comes standard with OTM upgraded hardend feed system, carbide quick change tooling, and state of the art PLC controls.

Run Rates In Parts Per Minute

- 9MM Luger – 180 – 200 PPM

- 45 ACP – 180 – 200 PPM

- 223/5.56 – 180 – 200 PPM

- 7.62×51 – 160 – 180 PPM

- 338 Lapua – 140 – 160 PPM

Press Details

- Tonnage: 220 Ton

- Electrical: 220/480V

- Stroke: 6″

- Coolant Capable: Yes

- Max Caliber Size: 338 Lapua

- Drive Type: Servo With Controllable Motion Paths

Previous

Next

OTM-5400 – Rifle Header

The OTM-5400 is a heading press for forming the primer pocket, flash hole and the rifle head. The servo capability has features such as tool temperature adjustment, multi program memory, and a adjustable head. This machine comes standard with OTM upgraded hardened feed system, carbide quick change tooling, and state of the art PLC controls.

Run Rates In Parts Per Minute

- 223/5.56 – 50-60 PPM

- 7.62×39 – 50-60 PPM

- 7.62×51 – 45-55 PPM

- 338 Lapua – 40-45 PPM

Press Details

- Tonnage: 80 Ton

- Electrical: 220/480V

- Stroke: 6″

- Coolant Capable: Yes

- Max Caliber Size: 338 Lapua

- Drive Type: Servo With Controllable Motion Paths

Previous

Next

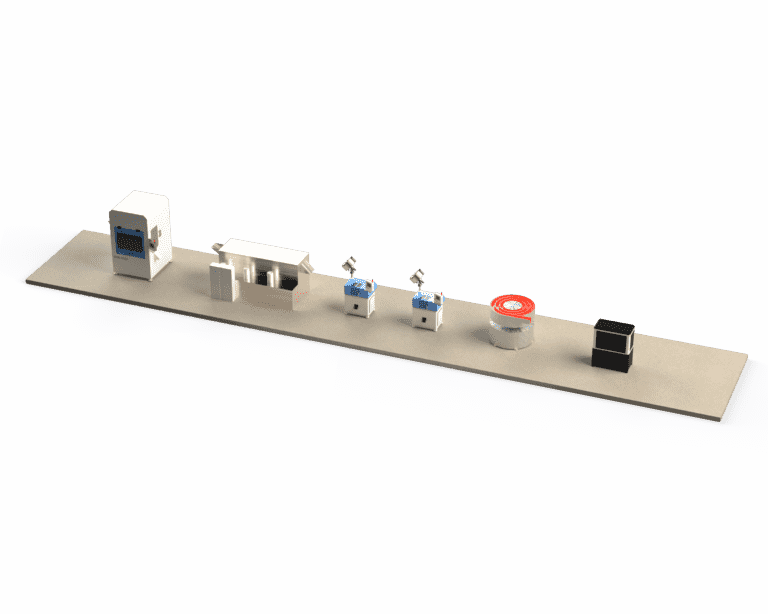

Complete Systems & Lines

OTM brass lines can be set up as conventional brass manufacturing lines or as completely automated systems with no human input for moving product. Each line is custom designed for its operation and final desired product. From 9mm to 30mm GAU 8, systems & processes can be developed to make your products at the investments you are looking for with the quality you need.

Brass can be formed from any three main processes, cup form, wire form, and strip form. Wire (shown right) being the most cost effective. This allows the end user to form up to 95% of the product being processed, where the tradition strip process only uses 75% of the processed materials.