- (989) 317-8033

- 801 Industrial Dr, Mt Pleasant, MI 48858

- Mon - Fri: 8:00 AM - 5:00 PM

OTM Cartridge Loading

OTM-30A & OTM-30B

The OTM-30A and OTM-30B were designed to be the loading machine for companies large and small. These machines are designed to run at lower run rates and easy tooling conversions to make it more flexibly for the end user.

General Machine Specifications:

- OTM-160B NGF With Quick Change System.

- Magnetic Door interlocks for operator safety.

- Complete Guarding with 1/4″ polycarbonate windows.

- Stationary powder hopper for easy refill during operation.

- 5″ color touch screen.

- Physical Touch Buttons for easy operator interfacing.

- Optional Over all length check features.

- Optional Powder check features.

- 110V Power Requirement.

- 100 PSI Air Requirement.

- Mechanical indexer with sensors and alignment pin for true position repeatability.

- Foot Print: 48″ x 36″

- Weight 950 LBS

OTM-30A

The 30A is a single powder drop pistol cartridge loading machine with a max production capability of 60 parts per minute.

OTM-30B

The 30B is a dual powder drop rifle cartridge loading machine with a max production capability of 50 parts per minute.

Previous

Next

Cartridge Loading Machine

OTM-3000LM

The OTM-3000LM comes standard with an OTM-300A feed system (a 30” feeder). OTM feeders have been proven in the industry to be safe, reliable and effective at keeping production rates up. The feeder is controlled on the main PLC and has low bowl indicators which let the operator know when the feeder needs to be filled.

The powder hopper is intentionally kept small to prevent injury if problems occur. The hopper is made from non-sparking materials that also help reduce risk of explosion. A powder delivery system can be arranged to be added to our machine; this is typically stored in a dry/blast room and transported to the machine.

To ensure that cartridges are assembled correctly, there are various checks that are done throughout the process to ensure an accurate finished product. Before the case enters the loading stations, the first dial has an inspection station to check for primer presents and mouth roundness. After the powder has been dispensed, there will be an optical check to validate the amount of powder was correctly installed. After the bullet is seated, there will be another optical check to validate whether or not the bullet is inserted to the correct length.

OTM-3000LM Continued

Machine Benefits & Features

- Continuous motion assembly process.

- Spring loaded pins on an upper cam follower to ensure accurate OAL and smoot bullet seating.

- Sound enclosure.

- OTM-300A feed system cases and bullets.

- Primer direction check with bad part eject.

- Mouth flaring station.

- Powder drop with volumetric measuring system.

- Bullet seat and crimping stations.

- In process bullet OAL check and bad part eject.

- Rotary cartridge insert that is mechanically timed to prevent from having operator adjustment.

- Stack light indicators to let the operator know feeder levels are low.

- Large touch screen PLC for machine controls.

- Internet connectivity for offsite machine troubleshooting.

- Product manual (digital and hard copy) that will include recommended ware parts, and daily maintenance.

- All steel parts will be heat treated and surface ground to prevent premature ware.

- 240 PPM+ run rate for 5.56 & 7.62.

- 300 PPM+ run rate for 9mm & 45 ACP.

- Power requirements 220V or 480V.

- 190” X 65” X 130” floor space.

- E-stop and other safety features.

- Machine guarding in ¼” clear polycarbonate.

- Safety sensors on machine guarding.

- All parts machined from billed aluminums, steels and stainless.

- All fasteners are stainless steel to prevent corrosion issues.

- All parts that can be will be coated for corrosion prevention.

- Solid steel frame and no blind holes to prevent areas where primer compound can gather and cause danger.

- Using solid steel instead of square tubing also adds weight which leads to machine rigidity.

- Smooth surfaces and removeable guarding to ensure easy clean up and maintenance.

Safe, Reliable, and Effective

The OTM-3000LM comes standard with an OTM-240A feed system. This is a 24” feeder. OTM feeders have been proven in the industry to be safe, reliable, and effective at keeping production rates up. Feeder is controlled on the main PLC and has low bowl indicators which let the operator know when the feeder needs to be filled.

Powder hopper is intentionally kept small to prevent injury if problems occur. The hopper is made from non-sparking materials that also help reduce risk of explosion. A powder delivery system can be arranged to be added to our machine; this is typically stored in a dry/blast room and transported to the machine via vacuum tubes.

Quality Checks

To ensure that cartridges are assembled correctly, there are various checks that are done in process to ensure an accurate finish product. Before the case enters the loading stations the first dial has an inspection station to check for primer presents and mouth roundness.

After the powder has been dispensed there will be an optical check to validate the amount of powder was correctly installed. After the bullet is seated, there will be another optical check to validate whether the bullet is inserted to the correct length.

The continuous motion case feed system ensures we can run as fast as possible without damaging parts. This machine is equipped with a case feed system that drop the cases into the stations while the machine is in motion still.

Continuous motion case feed system.

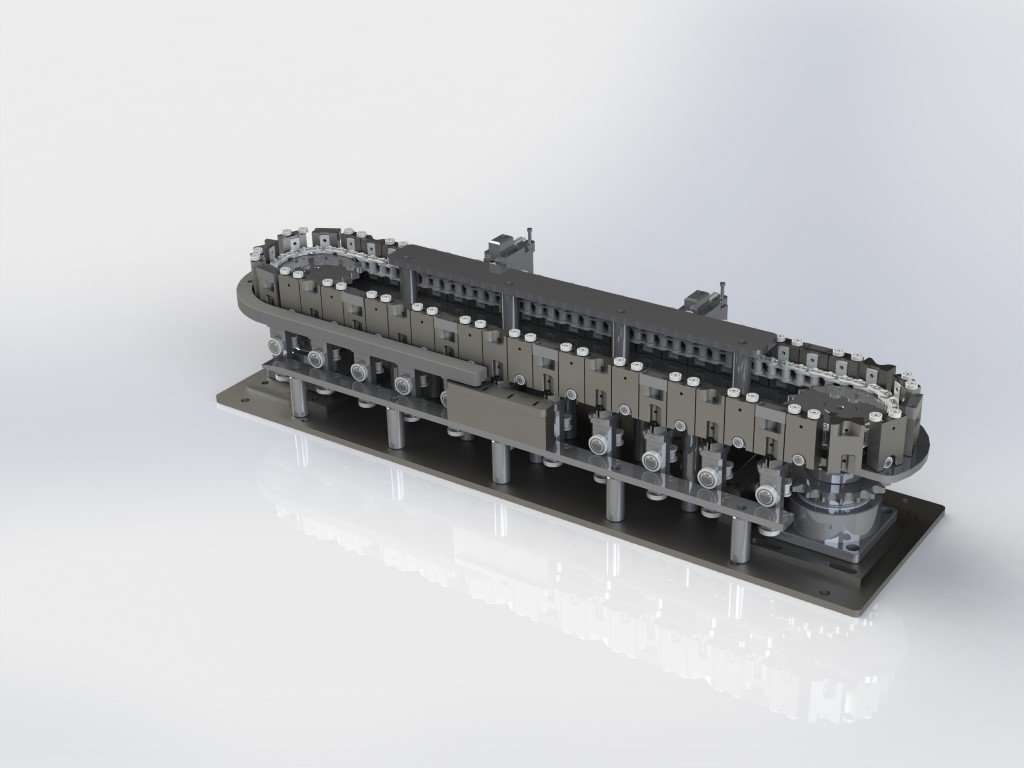

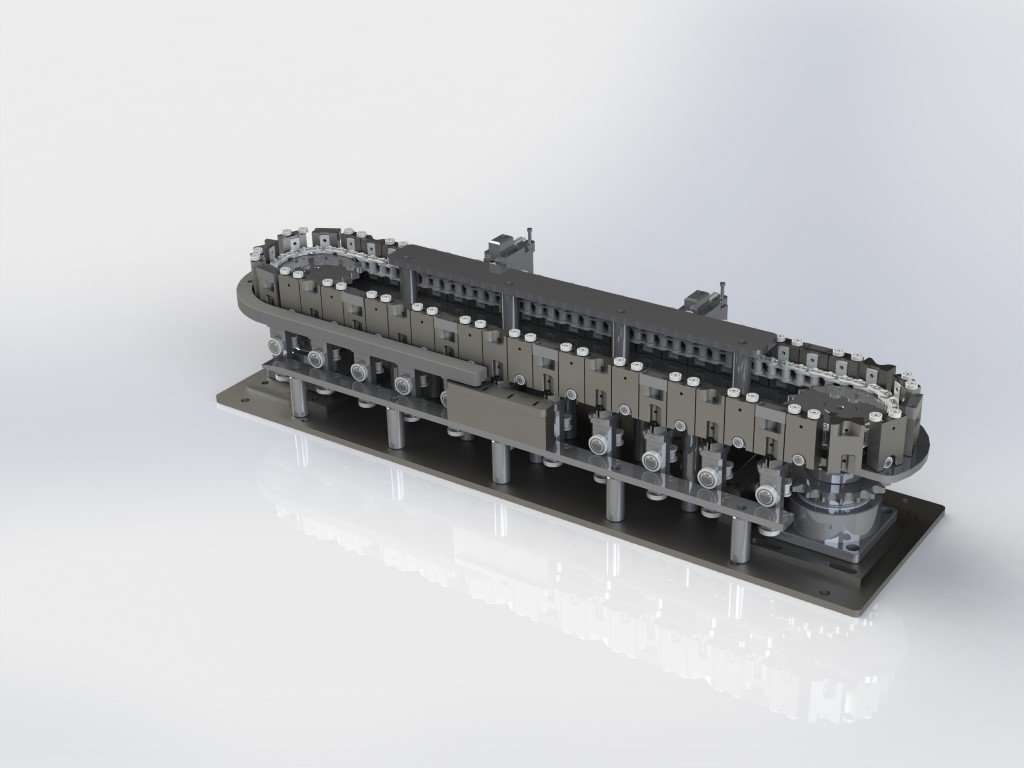

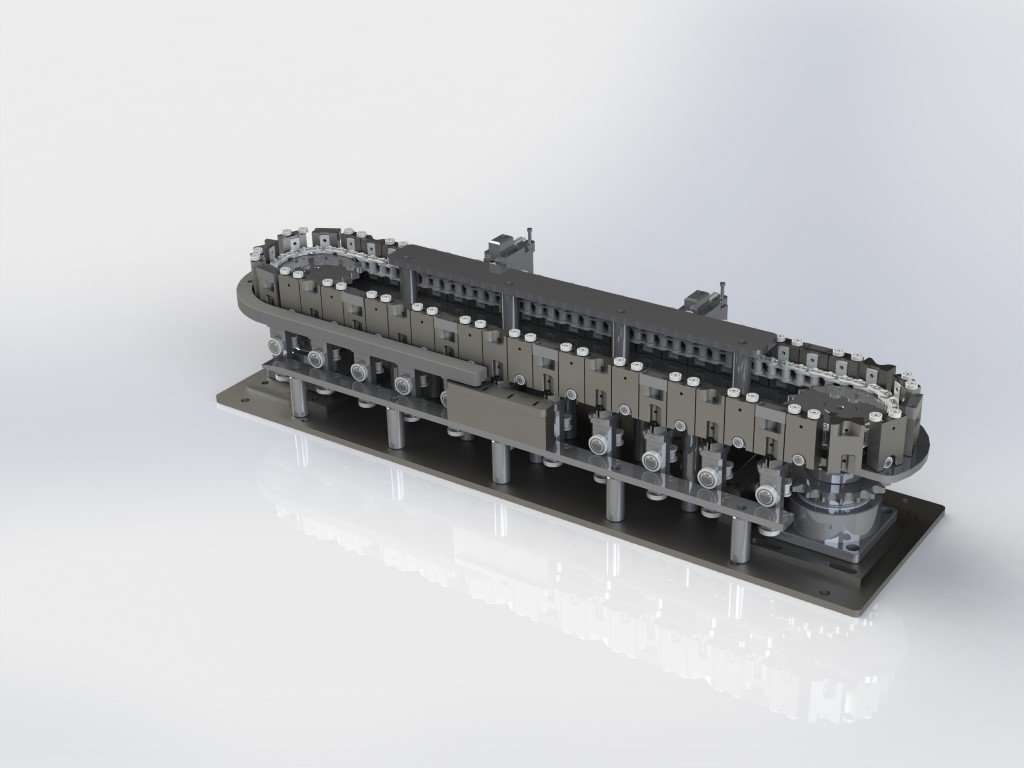

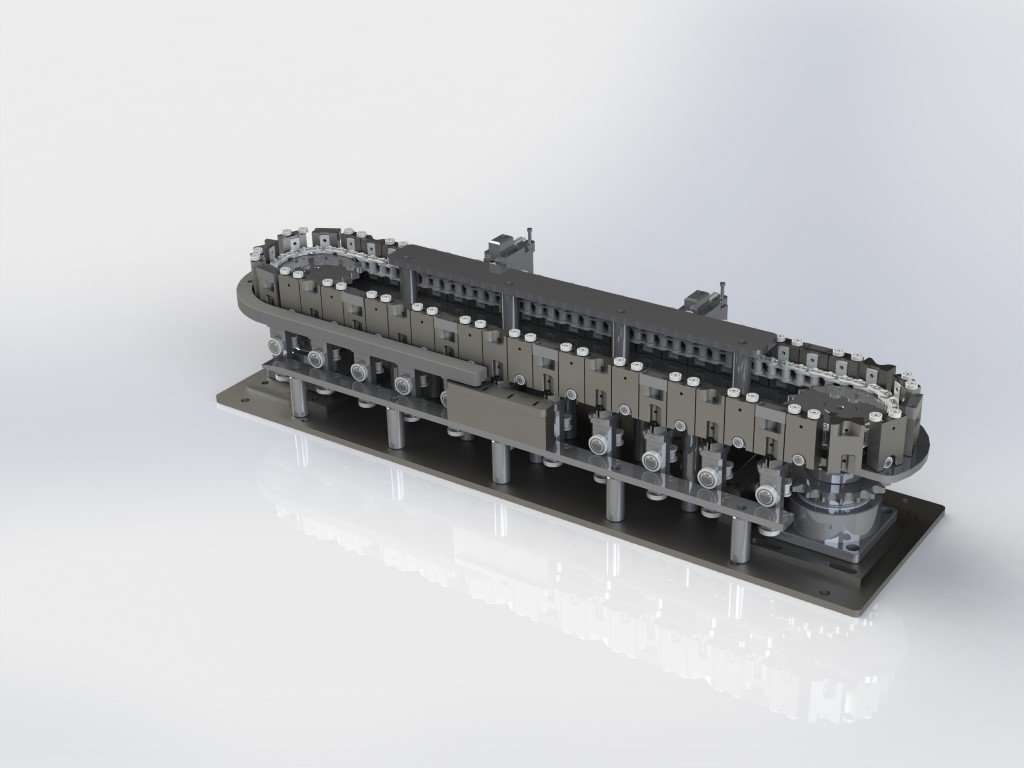

Station Holder

Station Holder

The station holder has spring-loaded precision-made fingers that hold the case through the whole process. This eliminates the need to transfer between processes and stop machine at each process. Each station has a vertical and horizontal alignment bearing which keeps the station lined up with the tooling above. These stations are connected with heavy duty No.80 roller chain, there are just under 200 identical stations on the machine.

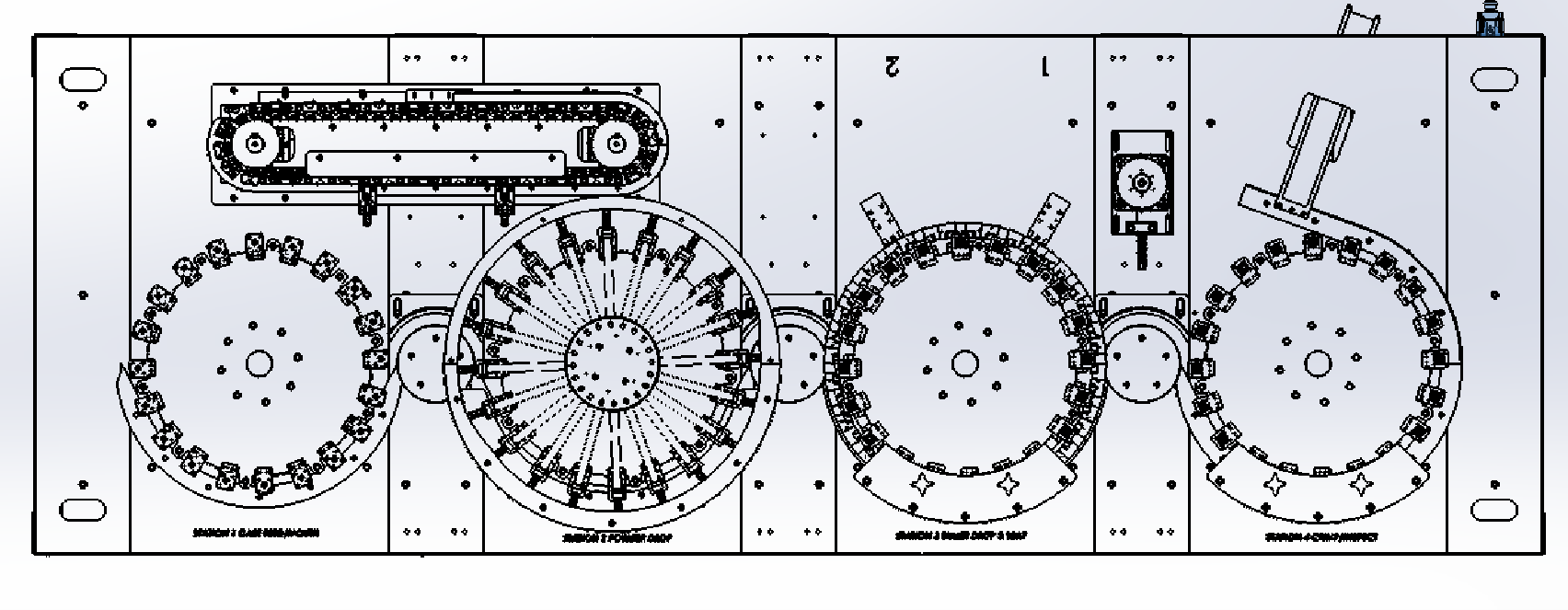

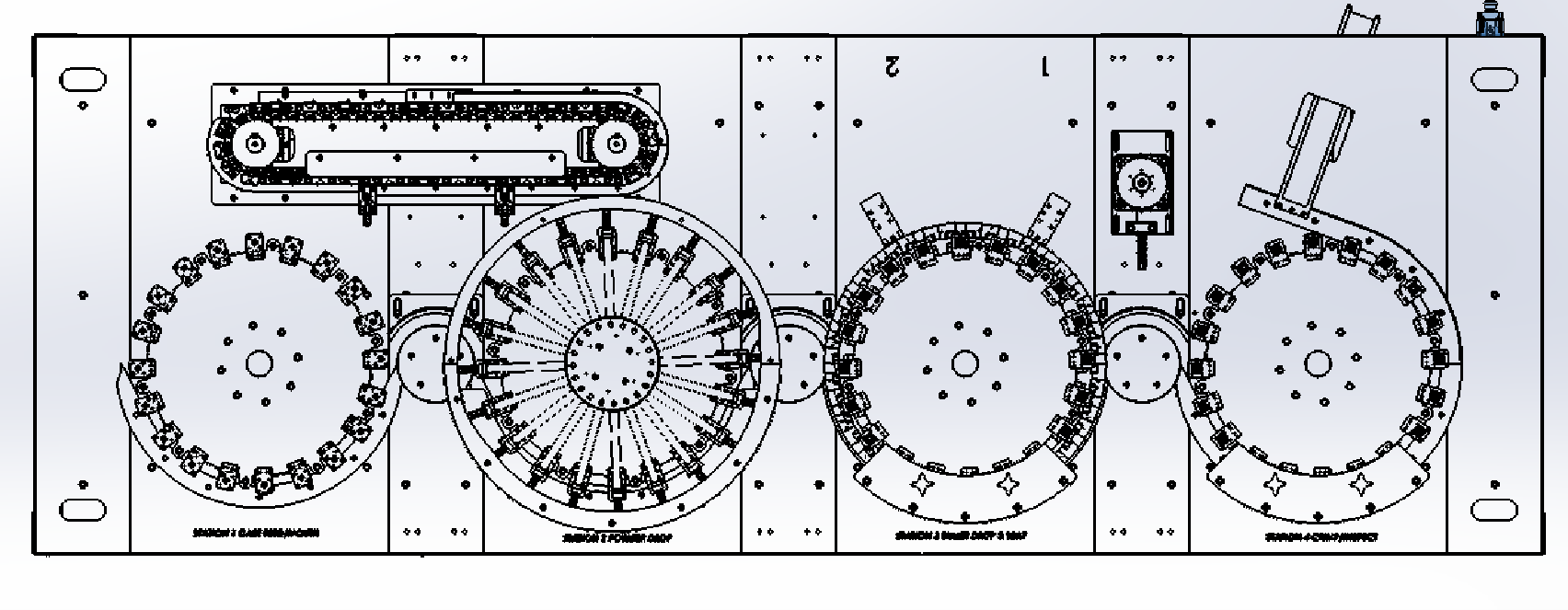

The below image shows the complete machine lay out with all of the stations and inspection points. The station travels in a counterclockwise serpentine path until it reaches the end where the loaded cartridge is ejected.

OTM-3000LM Machine Layout

Click on the red tooltips to learn more about each inspection point

Case Feed

In Process Inspection (3x)

Cartridge Eject

Mouth/Neck Sizing

Powder Drop

Bullet Drop/Seat

Crimp/Inspection

Modular By Design

The OTM -3000PM is designed in a modular concept that allows customers the ability to add custom processes or add machine capabilities when needed. Examples of things that can be added; inspection, transfer to other machines, and any other customer specific needs.

Machine Specs

Weight:11,850 lbs

Footprint: 175.25” x 60.25” x 80” (plus feeder height)

Electrical Requirements: 480V

Feed Systems: 2 (OTM-160A) 2 (OTM-240A)

Drive system: 10hp W/Gear Box

Caliber Ranges: 380 ACP – 338 Lapua (Caliber Specific)

PPM Rates: 300+ (Pistol) 240+ (Rifle)

Air Requirements: 100 PSI